Infrared measurement technology very compact

The detection and the measurement of gas concentration is a standard procedure in medicine and other industries worldwide. This explanatory article will look at what must be considered when selecting the components; and why multi-channel detectors and infrared emitters are essential.

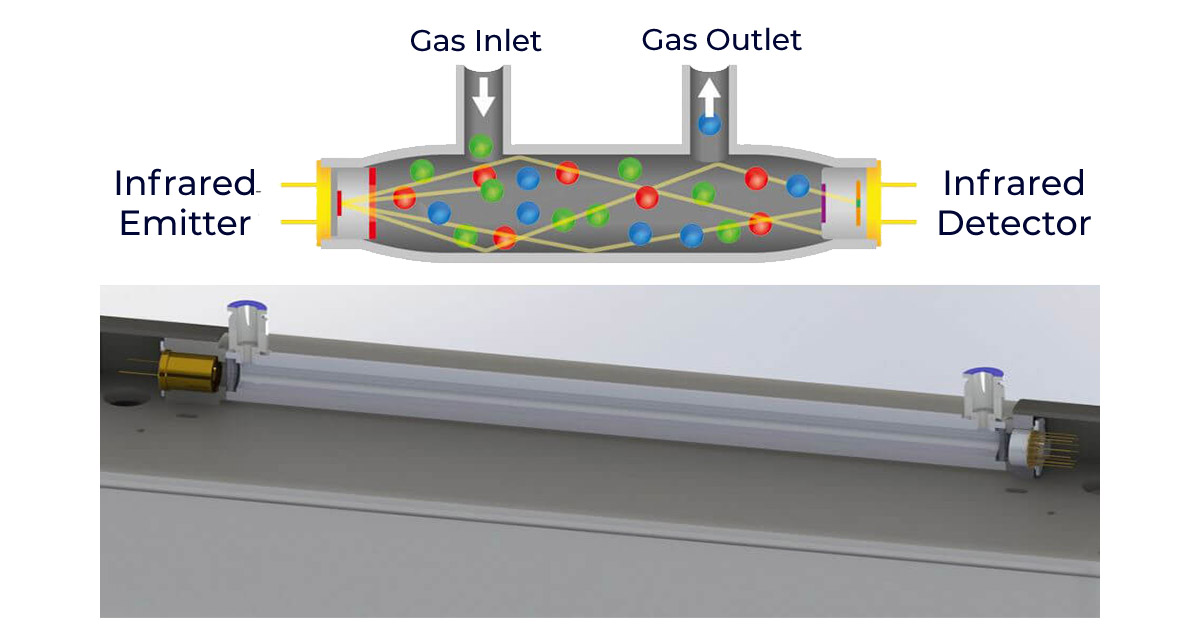

Figure 1: The basic and practical setup for NDIR gas analysis below shows a pyroelectric detector and an electrically modulated infrared source from Infrasolid (left) (Image: Infrasolid)

Almost every gas has the property of absorbing radiation of specific wavelengths in the mid-infrared range. This means that depending on the gas and the existing gas concentration, the radiation is specifically reduced. In Non-Dispersive Infrared gas analysis (NDIR gas analysis) this effect is measured and visualized. This allows gas concentrations to be determined accurately and with long-term stability, and cross-sensitivities with other gases can be reduced. The areas of application are diverse: from lung function diagnostics to the dosing of aesthetic gases, for personal safety equipment in mining and in industry as well as in environmental measurement technology such as exhaust gas measurement on chimneys and vehicles.

Depending on the concentration of the gases to be measured in the chamber, corresponding signals are generated on the detector channels by changing the intensities and compared to the reference signal. The reference channel also levels out drift effects, which may occur over the lifetime of the device due to aging of the infrared radiation source or contamination in the optical path of the infrared source.

Figure 2: Single (analog and digital), dual, & quad channel analogue TO-39 infrared detectors from Broadcom, now part of Broadcom (Image: Broadcom)

Physical basics of gas analysis

Many gases absorb infrared radiation at different wavelengths, depending on the gas, so that the gas can be identified by evaluating the spectral absorption. An NDIR gas analyser uses this principle. A narrow bandpass filter is integrated into the detector for each channel, the passband of which corresponds to the absorption wavelength of the target gas. The more channels, the smaller the sensor area of the individual channel and the more important a powerful infrared emitter.

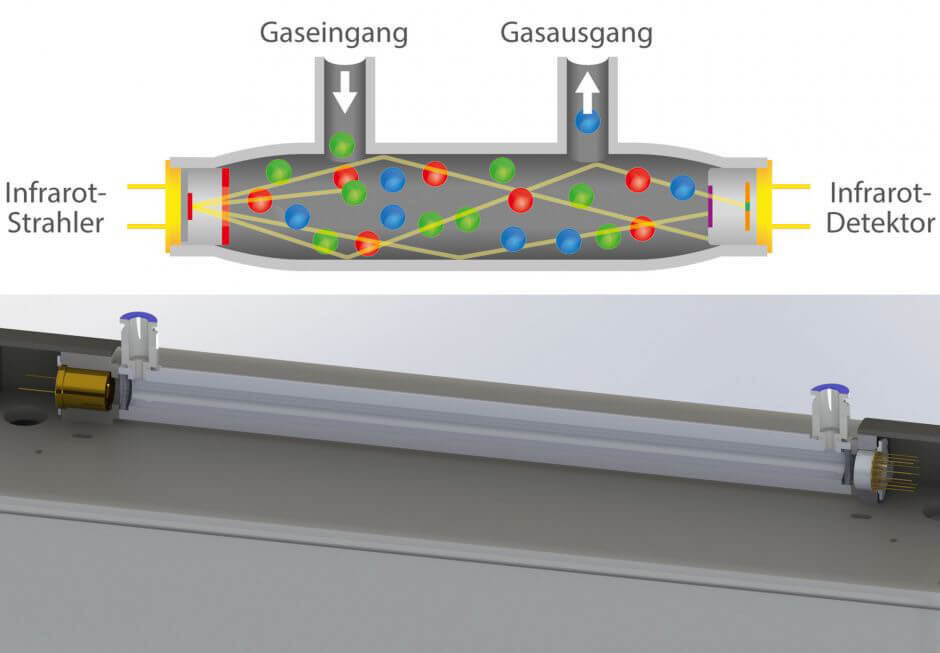

Figure 3: Signal gain from the Infrasolid emitters compared to other thermal infrared emitters in TO-8 housing. Depending on the wavelength, more than 500% signal gain is achieved. (Image: Infrasolid)

How is the infrared detector selected?

Broadcom pyroelectric detectors enable measurement over a large wavelength range and thus a device-side manageable, long-term stable, cost-effective and continuously working measurement method for gas analysis.

The simultaneous identification of many gases without cross-sensitivities in gas mixtures requires several spectral channels. For this purpose, Broadcoms optical sensing Division offers components with a patented design in which the radiation enters the detector. A lot of radiation reaches the pyroelectric elements, which in turn results in a high signal-to-noise ratio and offers great advantages for the users’ electrical amplification.

Pyroelectric detectors are suitable for gas analysis, since the pyroelectric crystals made of lithium tantalate (LiTaO3) installed in the detector change their polarization with a change in temperature. To enhance the pyroelectric effect, the pyroelectric LiTaO3 a highly absorbent black layer applied. If infrared radiation hits this layer, the pyroelectric heats up and surface charges are created. If the radiation is switched off, charges of reverse polarity are created. However, the charges are very small. Before they can equalize again due to the finite internal resistance of the crystal, very low-noise and low-leakage field effect transistors (JFET) or operational amplifiers (opamps) convert the charges into a signal voltage. Detectors with OpAmps (current operation) can be operated very quickly. Their high output signal can be further processed in an uncomplicated and low-interference manner.

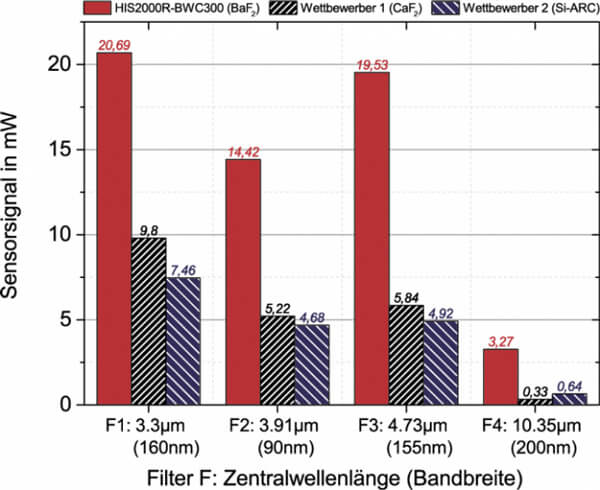

Figure 4: Basic structure of an infrared emitter from Infrasolid with a gold-plated reflector. (Image: Infrasolid)

The right infrared heater

The modulable emitters from Infrasolid (now part of Innovative Sensor Technology IST AG) provide broadband radiation. The electrical modulation eliminates the need for a mechanical chopper. As a result, the entire sensor can be made more compact and the systems are more robust due to the omission of mechanical parts. The patented design of the radiant Filament in the form of a double meander ensures high mechanical stability and at the same time increases the electrical resistance, so that the emitter can be operated with a low current. The high electrical resistance remains constant over the entire operation and leads to a very high efficiency and even heating of the entire filament. To significantly increase the emitted radiation power, the filaments are coated on both sides using a special process.

Infrasolid's TO8 infrared emitters deliver the highest sensor signal compared to other thermal infrared radiation sources currently on the market. Figure 3 compares the signal gain of the Infrasolid emitters with conventional infrared emitters in a TO8 package in a typical NDIR setup with a 4-channel detector and a cuvette length of 200 mm. It can be clearly seen that the infrared emitters from Infrasolid produce a signal that is 2 to 4 times higher than other thermal TO-8 emitters in the wavelength range from 3 µm to 5 µm and even a signal that is 5 times higher in the long-wave range at 10, deliver 35 µm.

This is due to the high temperature, large radiating area, and high emissivity of the radiating filament. Furthermore, a gold-plated reflector mounted on the TO base also throws the radiation emitted from the back forwards out of the cap opening and thus makes it usable (Figure 5), which leads to a further signal gain at the detector. By using Infrasolid emitters, the resolution of gas detection devices can be increased by a factor of up to 5. This leads to a significant increased performance in classic NDIR setups.

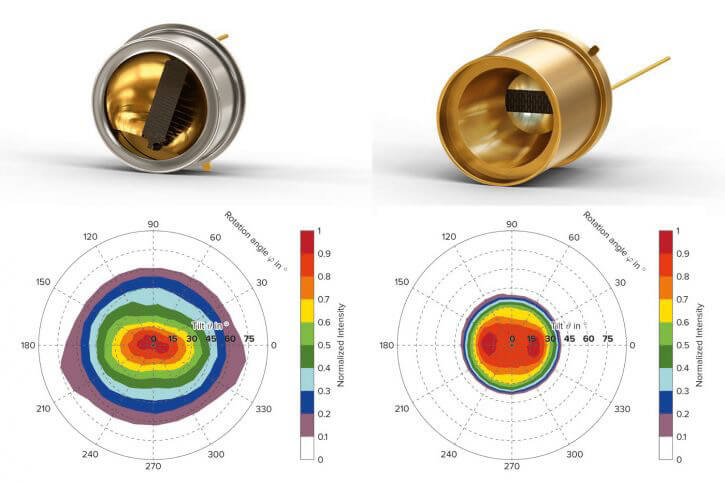

Figure 5: Emitter in TO8 housing with reflector (left) and with reflector and Winston Cone collimator (right); the optimized beam bundling is clearly visible in the graphic on the right. (Image 5: Infrasolid)

Additional reflections within the gas cell are particularly disruptive when water vapor partially condenses on the inner walls. To reduce reflections, Infrasolid emitters can also be fitted with a so-called Winston Cone collimator. This bundles the emitted radiation from the emitter and reduces the reflections on the cuvette wall until it hits the detector. Figure 5 shows the measured radiant power as a function of the radiation angle.

Figure 6: A possible area of application for IR emitters and detectors is in medicine, here they are used in anaesthetic gas monitoring. (Image: Fotolia)