The landscape of industrial automation is undergoing a significant transformation with the advent of Industry 4.0, a new phase characterized by an increase in automation and data exchange in manufacturing technologies. At the forefront of this revolution is the integration of smart machines, which are embedded with advanced sensors that enable them to analyze and process data autonomously. PixArt, a leader in sensing technology, is contributing to this shift by equipping traditional industrial machinery with intelligent sensors, such as the Optical Tracking Sensor (OTS) and Optical Encoder series. These sensors are pivotal in refining the precision and reliability of motion control systems, which are integral to the functionality of modern manufacturing equipment.

The landscape of industrial automation is undergoing a significant transformation with the advent of Industry 4.0, a new phase characterized by an increase in automation and data exchange in manufacturing technologies. At the forefront of this revolution is the integration of smart machines, which are embedded with advanced sensors that enable them to analyze and process data autonomously. PixArt, a leader in sensing technology, is contributing to this shift by equipping traditional industrial machinery with intelligent sensors, such as the Optical Tracking Sensor (OTS) and Optical Encoder series. These sensors are pivotal in refining the precision and reliability of motion control systems, which are integral to the functionality of modern manufacturing equipment.

THE ADVENT OF SMART MACHINES IN INDUSTRY 4.0

PixArt'Industry 4.0 marks a significant shift towards automation and smart factories where machines are not only interconnected but also capable of making decisions based on real-time data. The role of smart machines in this industrial evolution is to streamline production processes, reduce human error, and increase efficiency. Sensor technology is the cornerstone of these intelligent systems, providing the necessary data for machines to operate autonomously.

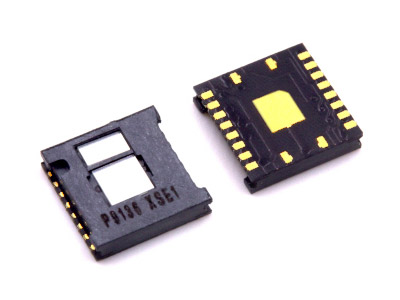

PixArt's Optical Tracking Sensor, specifically the PAT9136E1-TXQT model, exemplifies the kind of innovation that is propelling Industry 4.0 forward. This advanced CMOS imaging sensor is capable of tracking the movement of surfaces with a resolution of up to 20,000 counts per inch (cpi), offering unparalleled precision in motion control. The sensor's output, delivered in a serial data format via an SPI interface, allows for seamless communication with microcontroller units (MCUs), making it an essential component in the modernization of industrial machinery.

PixArt's Optical Tracking Sensor, specifically the PAT9136E1-TXQT model, exemplifies the kind of innovation that is propelling Industry 4.0 forward. This advanced CMOS imaging sensor is capable of tracking the movement of surfaces with a resolution of up to 20,000 counts per inch (cpi), offering unparalleled precision in motion control. The sensor's output, delivered in a serial data format via an SPI interface, allows for seamless communication with microcontroller units (MCUs), making it an essential component in the modernization of industrial machinery.

UNVEILING PIXART'S OPTICAL TRACKING SENSOR (OTS)

The PAT9136E1-TXQT OTS from PixArt represents a leap forward in the field of industrial sensing. Unlike traditional position sensors that may struggle with accuracy and flexibility, the OTS boasts a wide working range of 5-50mm from the tracking surface and can handle speeds up to 5m/s. This level of performance ensures that the sensor can maintain a low resolution output variation of less than 1% when operating at a fixed speed and height, and around 3% with varying conditions.

The PAT9136E1-TXQT OTS from PixArt represents a leap forward in the field of industrial sensing. Unlike traditional position sensors that may struggle with accuracy and flexibility, the OTS boasts a wide working range of 5-50mm from the tracking surface and can handle speeds up to 5m/s. This level of performance ensures that the sensor can maintain a low resolution output variation of less than 1% when operating at a fixed speed and height, and around 3% with varying conditions.

The ability of the OTS to work on a broad range of surfaces, including both metal and non-metal types, offers a versatility that is crucial for adapting to different industrial environments. This flexibility is particularly beneficial for after-market applications where the sensor needs to be integrated into existing motion control systems.

ENHANCING CLOSED-LOOP SYSTEMS WITH OTS

Closed-loop systems are essential in modern manufacturing for their ability to provide precise control over machine operations. By using sensors to return real-time data on the position or velocity of motors, actuators, and moving surfaces, these systems can adjust outputs to maintain desired performance levels.

Integrating the OTS into closed-loop systems enhances their functionality by providing additional feedback that can be used to correct any discrepancies between the intended and actual movement of machinery. For example, if a conveyor belt experiences slippage, the OTS can detect this and provide data to adjust the motor's speed, ensuring that the belt moves at the correct pace. This direct measurement of the medium's movement by the OTS is invaluable for maintaining the integrity of the motion control system.

SURFACE TRACKING: A GAME-CHANGER FOR MANUFACTURING PRECISION

The ability to track various types of surfaces with high precision is a game-changer for industries that rely on accurate motion control. The OTS's adaptability to different working surfaces allows it to be used in a wide array of applications, from the precise movement of robotic arms to the delicate handling of materials on production lines.

The ability to track various types of surfaces with high precision is a game-changer for industries that rely on accurate motion control. The OTS's adaptability to different working surfaces allows it to be used in a wide array of applications, from the precise movement of robotic arms to the delicate handling of materials on production lines.

Consider the example of a robotic painting system where the quality of the final product depends on the robot's ability to track the surface it is painting accurately. The OTS can provide real-time feedback on the robot's position relative to the workpiece, ensuring that each coat of paint is applied with consistent thickness and precision, regardless of the surface material or color.

INTEGRATING OTS INTO EXISTING INDUSTRIAL SYSTEMS

The integration of the OTS into existing industrial systems is a straightforward process, thanks to its design that allows for easy communication with MCUs. This ease of integration means that the OTS can be added to enhance the feedback loop of motion control systems without the need for complex imaging processing or motion computation algorithms.

The integration of the OTS into existing industrial systems is a straightforward process, thanks to its design that allows for easy communication with MCUs. This ease of integration means that the OTS can be added to enhance the feedback loop of motion control systems without the need for complex imaging processing or motion computation algorithms.

For instance, in a packaging facility where items of various sizes and shapes are sorted and packaged, the OTS can be used to track the movement of the conveyor belts and the items on them. By providing precise data on the position and velocity of the items, the OTS ensures that they are correctly aligned for packaging, reducing waste and improving efficiency.

CONCLUSION

The integration of PixArt's Optical Tracking Sensor technology into industrial automation systems marks a significant step towards realizing the full potential of Industry 4.0. With the PAT9136E1-TXQT model leading the charge, PixArt is setting a new standard for motion control precision and reliability. Electronic engineers looking to push the boundaries of what's possible in automation will find PixArt's OTS and Optical Encoder series to be invaluable tools in their arsenal. As we continue to witness the evolution of smart manufacturing, the role of advanced sensors like those developed by PixArt will only become more critical in shaping the factories of the future.